From Jack to Jointer: Navigating the World of Bench Planes

In this Toolbox episode I'm trying to understand the complex world of bench planes and break it down into a beginner friendly format.

New to The Woodworking Shed? I’ve got you covered! I've made this handy index page to find every episode in this series and more!

Here’s a link to the previous episode!

Understanding Bench Planes

Welcome back to The Woodworking Shed! This week I’m covering my favourite woodworking topic - Bench planes!

Bench planes are the most important part of my beginner’s woodworking toolkit (For me at least!).

Ever since I found an interest in woodworking, planes have fascinated me. Their ability to transform rough lumber into silky smooth surfaces amazes me. I really can't wait to own one (or all) of them!

It’s been a long road to get to this point. I've spent countless hours researching, watching videos, and reading reviews to figure out exactly what I need without it costing an arm and a leg…

I’ve done some of the hard work so you don’t have to!

Starting From the Beginning

As with most of the tools I am buying - I have zero experience with bench planes, so research is a must. They are complex beasts so before I can move forwards with buying any i need to understand them better.

Researching bench planes has been great fun, although I do get distracted a lot when watching videos. I find myself just watching the shavings and not listening! The next thing you know they’re talking about frogs and I’m completely lost. Ribbit.

“The Frog” is one of the parts of a plane

There is just so much to learn! I’ve broken it all down into a few key areas to cover:

Cost

Wood or metal

Old or new

Types of bench plane

Bench plane sizes

I’m going to try my best to go through all of these and hopefully find a path through the minefield that is bench planes!

Buying on a Budget

Cost is always a factor when buying tools, especially where a budget is involved!

The cost of bench planes varies wildly, more than any other woodworking tool I've looked at. There's the basic planes that cost £20 which are probably better used as paper weights!

On the other end of the scale, there's the premium planes that cost so much money that I could buy a whole toolkit for the price of one plane.

These are exceptional tools but I don't think as a beginner they should be a consideration. You miss out on all of the important lessons encountered when working with lesser tools.

Quality tools on a Budget is the way forward!

Wood or Metal

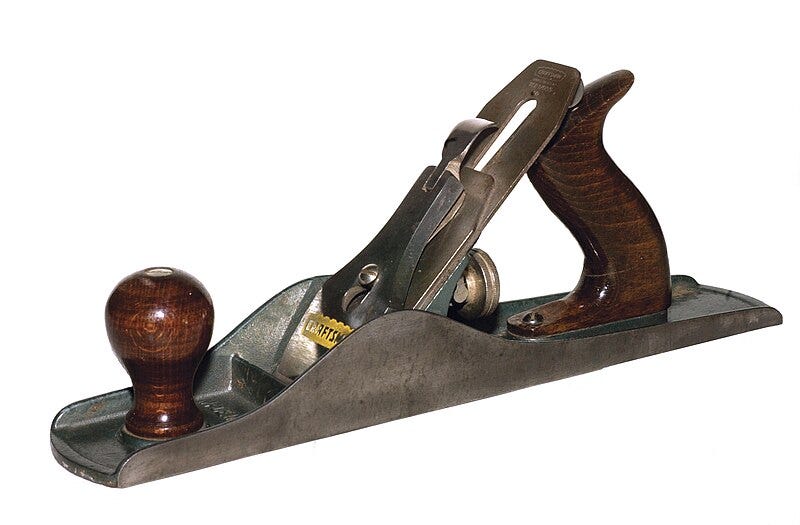

Some planes are made of wood, some are made of metal. As far as I can see, getting one or the other is just a preference. They do the same thing!

Wooden planes are lighter than their cast iron counterparts, which gives an advantage of you plan to use them all day.

Metal planes have more adjustability with settings for depth of cut and blade angle. I don’t want to have to use a hammer to adjust my plane!

The more precise adjustability of the metal plane also appeals to my inner engineer.

A downside of metal planes is that they are made from cast iron. It’s brittle and it rusts! Dropping it may mean the end of the line and and poor maintenance will ruin it!

If you look after them and they will last forever, or at least long enough that when they fail it will be someone else’s problem.

There are metal planes out there in use that are over 100 years old!

For a beginner, I think that metal planes are a better choice. For me, they are the only choice. The cast iron Bailey and Bedrock designs are half of what drew me to become fascinated with planing in the first place!

Wood or metal, what’s your preference? Let me know in the comments!

Figuring Out the Types of Bench Plane

It's pretty daunting at first. But when you drill down into it bench planes can be separated into three categories: Smoothing, Jack(Fore), and Jointer.

Not the most helpful names for a beginner but they do tell us what they are for and how big they are:

Smoothing planes are the smallest. They are used to finish a surface, Leaving - would you believe - a smooth finished surface.

Jack planes are medium-sized planes. They are used for removing material quickly to obtain the target thickness and for removing cups and bows from boards.

Jointer planes are the longest planes, they are used for flattening once the material has been brought roughly to size using a jack plane.

As I build up my woodworking toolkit I’d like to have one of each type. It isn’t necessary though, a lot of people get by with just a smoothing plane or a jack plane. This is understandable when you also factor in that regardless of size, they all do the same thing - take shavings.

In fact, the “Jack” in Jack plane is short for Jack of all trades!

I still want them all though!

Understanding Bench Plane Sizes

Knowing the three types of bench plane is only half the battle. Each of those types has several sizes!

There are eight core sizes of bench plane found in the classic Stanley numbering system with a couple of half sizes (and more but let’s keep it simple!) thrown in for good measure.

At this point it’s tempting to just suck it up and buy them all! It would be easier…

Realistically though I need to whittle down this list and figure out which ones I’m going to buy!

Thankfully, they go up in order of size:

Smoothing Planes - No.1, No.2, No.3, No.4, No.4.5

Jack/Fore Planes - No.5, No.5.5, No.6

Jointer Planes - No.7, No.8

The most popular plane sizes for each type are the No.4, No.5 and No.7. These are considered to be the most versatile. If you have these three, adding more won’t add much value. Here is a useful article explaining the sizes.

Choosing Sizes

For a while, I was set on getting a No.4 and No.5, they're the most popular so it was the obvious place to start!

However, I received some advice in my comments that a No.4 and No.5 are quite similar in size and that the smaller No.3 would provide more benefit.

As I definitely want a Jack plane, I’ve decided to take this advice and will be adding the No.3 and No.5 to my woodworking toolkit.

I'd love to get a No.7 as well to have one of each type but I'm sticking to my rule: My projects dictate my toolkit, and a Jointer plane isn't really necessary for building a workbench.

Wouldn’t it be nice to have a full set, though?

The Real Challenge Awaits…

I feel like I'm off to a great start with my bench plane journey. I have a much better understanding of the different types and sizes. I've even picked which sizes I want!

Now it's time for the real challenge: Choosing which ones to buy!

There's so many different brands out there, then there's vintage restoration… I'm really only half way through the minefield that is the world of bench planes!

I still have a long way to go, make sure to stay tuned for the next part!

Which plane did you get first? Let me know in the comments!

How You Can Help!

Just hitting that like button on my posts helps me to get The Woodworking Shed noticed!

If you'd truly like to support my mission to make woodworking more accessible, you can do so by becoming a paid subscriber or by buying me a coffee!

Early bird paid subscribers get 33% off forever!

Your support directly enables the growth of The Woodworking Shed and supports accessible woodworking!

Look forward to hearing from you -

~ The Woodworking Shed

Hungry for more?

Here’s the next episode!

Check out my other content! Head over to the homepage to find it all!

Like many, I’m sure I’ve been overly influenced by watching Paul Sellers and Richard McGuire on YouTube. My first plane, a Stanley no. 5, I inherited from my grandfather. He bought it brand new in the 1930’s. To this, I added a vintage Stanley no. 3, and no. 7, for smoothing and jointing. They are both over 100 years old, and after sharpening and a little tuneup ready for another century of work.

I also managed to find a couple of specialty planes…an older Stanley low angle block plane, a vintage no. 78 moving fillister (rebate) plane, and a no. 50 combination plane (still working on completing the set of irons). This handful of old Stanley’s can handle most of my current needs.

Over the last 18 months I've acquired quite a collection. To start with I bought a #4 smoothing plane, a block plane, and a spokeshave to start. Next I bought one of Sellers' router plane kits. Last year I bought a #5 jack plane, a vintage Stanley #5 that I'm turning into a scrub planes, any a vintage Stanley #7 jointer, and a vintage Stanley #78. I think I'm done, except for some beading planes. Why so many? The first three kept coming up in answer to, what should I start with. I bought everything else after watching and reading about my first projects, my bench and a tool chest. Saddly, I've had to push retirement back to September, today. I'm really miserable about it.